Kennametal Cutting & Wear Solutions

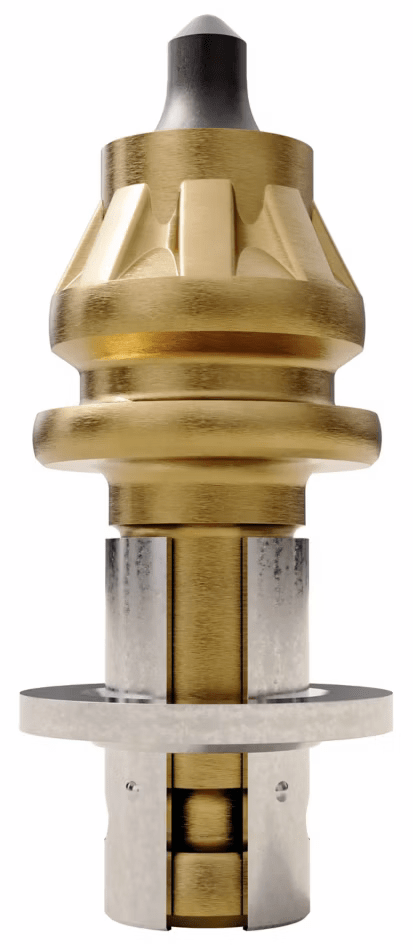

Bin Shehab Co. partners with Kennametal, a global leader in tooling and wear protection, to provide advanced cutting systems that maximize productivity, extend tool life, and reduce downtime in demanding applications across Saudi Arabia.

Our Kennametal solutions support industries in road rehabilitation, trenching, and foundation drilling with proven technology and unmatched durability.

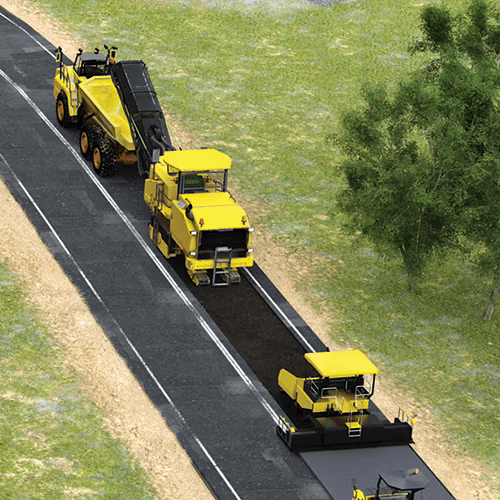

Road Rehabilitation

Road rehabilitation subjects your tooling equipment to extreme wear. Kennametal cutting tools are engineered for long tool life, excellent holder protection, and smooth machine operation, helping you work longer and more productively.

With KenCast™ wear protection, you avoid costly repairs and downtime, ensuring your equipment keeps performing on the road.

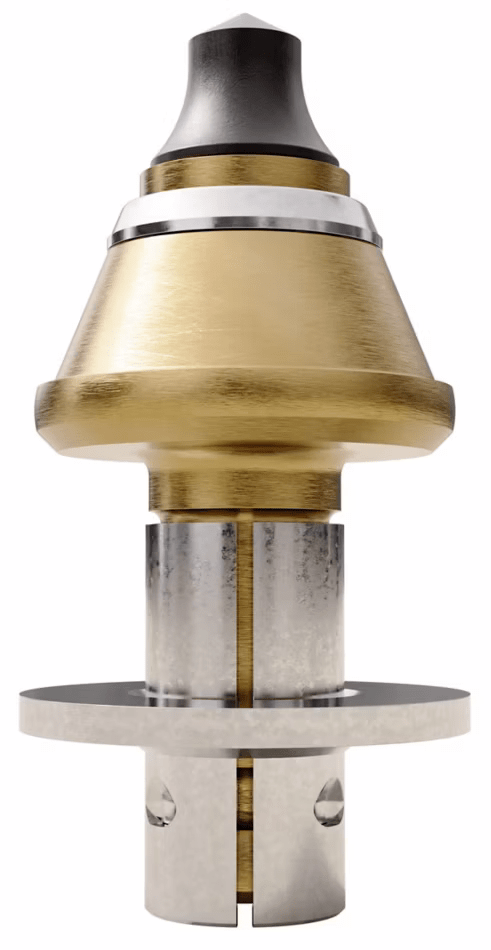

Trenching

Kennametal trenching systems are designed to boost productivity and protect your equipment. By selecting the right cutting tools from the start, you can meet production goals while minimizing costly downtime.

Our wear-protection solutions extend the service life of trenchers and drills, reducing maintenance costs and keeping your operation efficient.

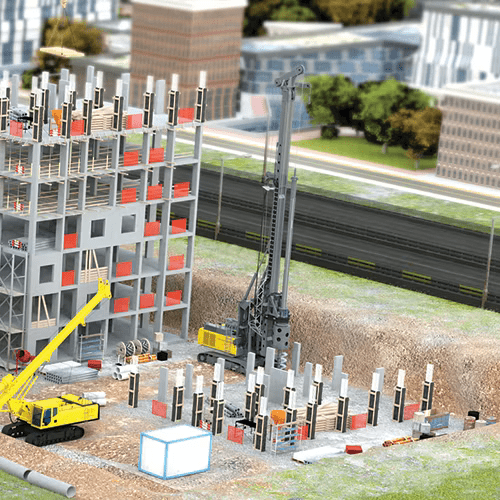

Foundation Drilling

Successful foundation drilling requires precision and reliability. Kennametal cutting systems are built to handle a wide range of foundation drilling attachments and geotechnical conditions.

These tools maximize wear resistance, improve drilling efficiency, and ensure less downtime — helping you complete foundation projects faster, safer, and with better overall performance.

With Bin Shehab and Kennametal, you gain access to proven cutting technology that delivers longer tool life, lower operating costs, and higher productivity.